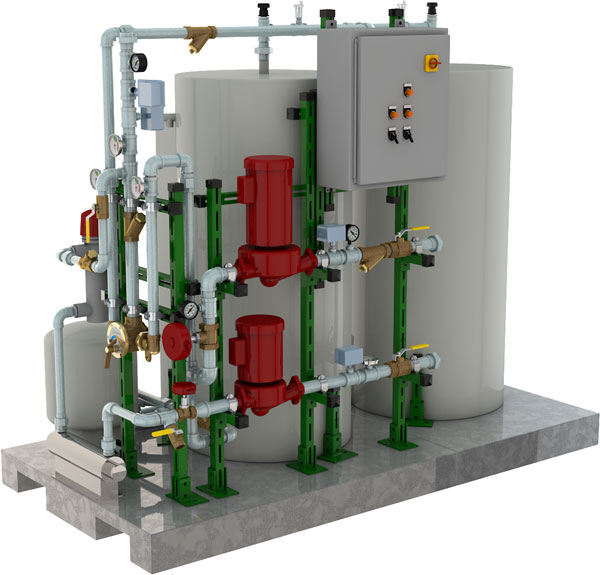

Tempering System, Recirculating, Dual Water Tank with Booster Pump

Application: Turnkey, skid-mounted tempering and recirculation system supplies tepid water to multiple looped emergency showers/safety stations in areas where hot water supply is not readily available, emergency fixtures may be spaced far apart, and incoming water pressure may be insufficient to adequately support proper fixture function. Recirculation system continuously circulates tepid water for immediate use even at fixture furthest from water heater. Upon fixture activation, tempering system blends hot and cold water to resupply system loop with tepid water. Note: Supports multiple activated showers at any given time in a looped system with low incoming water pressure.

Control Panel: UL listed, factory pre-wired electrical panel with single point connection and fused disconnect for electrical components. Includes recirculation heater, recirculation pump, and booster pump status indicator lights. Panel also includes recirculation system and booster pump power switches.

Variable Frequency Drive (VFD): Adjustable speed drive controls system pressure by adjusting pump speed to compensate for outlet pressure fluctuations. VFD maintains optimal system pressure during equipment activation and deactivation, thereby reducing the risk of water hammers and prolonging the life of critical system components.

Booster Pump: Custom sized factory installed pump boosts incoming water pressure to psi required for proper emergency fixture operation. Reverse acting pressure switch shuts down pump on pressure loss. Included in-line pressure gauge displays system pressure.

Water Heater: Two (2) 119 gallon tanks, each with factory installed 9 kW heater set to 160°F (71°C). Tanks include vacuum breaker, air eliminator valve, and temperature and pressure relief valve. System recovery time is 3-1/2 hours with an incoming water temperature of 50°F (10°C).

Expansion Tank: 10.3 gallon tank for pressure relief due to thermal expansion within the tempering skid.

Thermostatic Mixing Valve: Model G3900LF mixing valve for emergency eyewash and shower units. Valve has a flow rate of 3-81 GPM. Bimetallic thermostat preset to 85°F (29°C) with high temperature limit stop set to 90°F (32°C). Valve includes thermometers on inlets and outlet to monitor water temperatures. In the event of hot water supply failure, internal bypass allows valve to deliver cold water. In the event of cold water supply failure, valve will close and not deliver water.

Recirculation Pump: Custom sized factory installed recirculation pump with reverse acting pressure switch to shut down pump on pressure loss.

Recirculation UV Light: In-line ultraviolet water purifier eliminates unwanted bacteria from tepid recirculation system.

Recirculation Heater: In-line heater maintains tepid water in recirculation line. Heater thermostat is preset to 85°F (29°C). Included external, redundant temperature switch deactivates heater if outlet temperature exceeds 95°F (34°C).

Recirculation Inlet: 1-1/2” solder cup dielectric union connection.

Recirculation Outlet: 1-1/2” solder cup dielectric union connection.

Cold Water Supply: 1-1/2” solder cup dielectric union connection.

Pipe and Fittings: IPS schedule 40 galvanized pipe and fittings with brass ball valves, brass check valves, and strainers.

Quality Assurance: Water heater, mixing valve system, and recirculation system (including all electrical controls) are thoroughly tested prior to shipment. Some assembly required in field.